The diameter of the pulley has an important influence on the life of the belt. The catalog value of the smallest pulley diameter must be taken into account. The recommended diameter generally increases the number of belt bends, thereby accelerating belt fatigue and shortening belt life. Our smallest pulley diameter indication is based on the neutral layer of the area, at an environmental angle of 180 °. This is the contact angle at which the belt is guided around the pulley.

Our values are recommendations and may vary slightly depending on the specific circumstances. The strength and fatigue of the material are affected by the design of the conveyor, bending frequency and actual application / process.

Our proposal is based on the following premises: the belt is folded every 2 seconds, the distance to the center of the belt is 2m and the constant speed is 1m / s. For specific calculation support, contact our application engineers or send a complete technical questionnaire.

Pulleys for round belts

Select the appropriate minimum pulley diameter according to the various PU / polyester qualities. When it comes to plastics, the most suitable materials for pulleys are steel, steel alloy, aluminum or polyamide. When using plastic, consider the low friction coefficient μ.

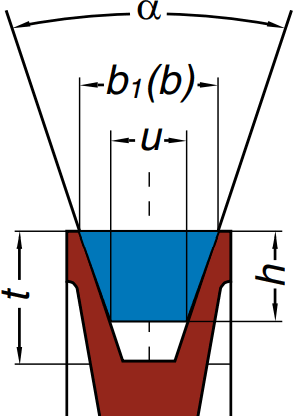

Recommended pulleys for V-belts

V-belts according to DIN 2215 / ISO 4184 pulleys for V-belts according to DIN 2217/ ISO 4183 have to be used.

Design of pulleys for belt profiles

Considering the pairing of belts and pulleys, it is generally recommended to use materials and / or surfaces that produce enough friction for PU / TPE. Aluminum or steel. This is important to ensure proper energy transfer. Please note that aluminum can cause the belt to discolor (black). All other pulleys, guide elements or sliders must be made of low friction materials such as PE or HDPE.

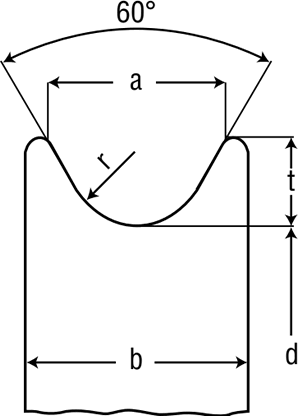

Grooved pulleys for round belts

For simple transport, these pulleys are generally the same as those used for V-belts. However, the V-belt pulley is not the ideal choice because the diligent notch can actually hold the round belt and cause premature damage. Therefore, it is recommended to use a special round pulley. Unlike the V-belt, the round belt must come into contact with the sides and the bottom of the groove, and these factors must be taken into account in the manufacture of the respective pulleys.

Pulleys for T-Profiles

The power transmission of this type of belt occurs in the flat area of the back. This means that the V-rail is not a component used to transmit power, but only for guiding purposes.

Therefore, the guide plate must be able to move freely in a small space and must not be tightened!

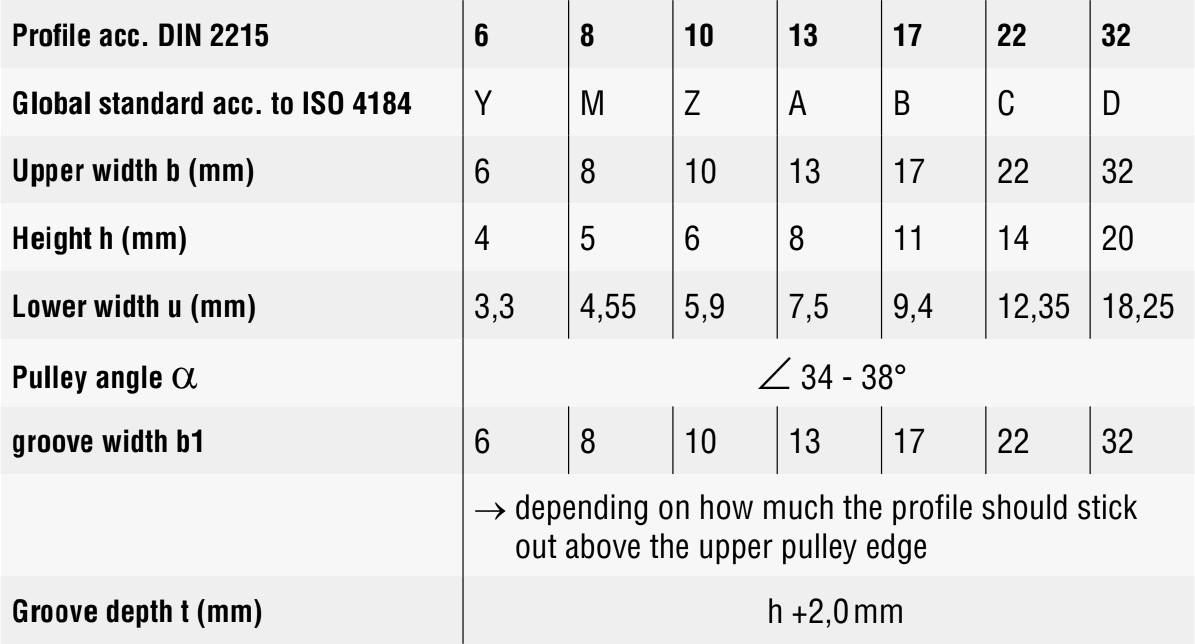

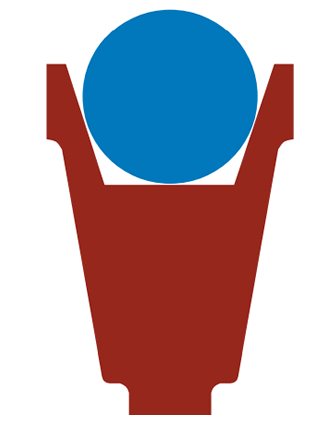

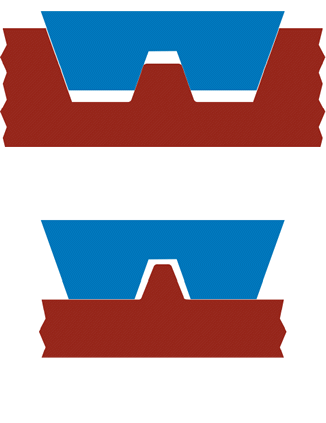

Pulleys for Twin V-belts

For the parallel V-belt, there is a difference between being used as a process conveyor belt or as a diffusion belt.

When driving, the design of the pulley should make the power transmitted from the side.

In paver applications, it has proven to be a good idea to specifically guide the belt through the center groove and drive the belt through the underside of the profile.