How does the pretension of a belt impact its lifespan?

Correct pretensioning of the belt is critical to the performance of the belt, as well as choosing the right belt and the right splice system.

For recommended complaints, refer to the product table for each area in the delivery procedure.

Impacts of wrong pretension:

Claims that are too low will cause the belt to slip and generate excessive heat. This can lead to belt deformation, heavy wear, breakage and jump out of the pulley.

Excessive claims can damage pulleys, shafts and bearings. The belt is still too tight and will fail prematurely due to material fatigue and cracking. In addition, the belt loses the durability of the material.

Tension device

Various tension devices can be used to accommodate different amounts of tension in the area or to aid the instillation process. In addition, for reinforced belts or areas requiring little pre-stressing, we recommend the use of tensioning devices permanently installed on the transport system.

Please follow our recommendations and claims for each belt to reduce premature wear and bearing failure.

Common ways to properly tension the belt are as follows:

- Cut the belt to a length less than the length measured by the conveyor system

- Use a gripping pulley or side pulley with counterweight or mechanical movement of the screw

- Use an adjustment screw to move the motor into the mounting hole of the slot

- Elongated slide (the drive motor is installed on the rail and moved by its own weight or by a screw mechanism)

- Sealed upper jack (the motor with steering wheels is installed on the rotary rocker arm. If the drive motor turns in the specified direction, then the rear motor torque automatically tightens the belt)

The correct position of the tensioner pulley is critical to the life and functioning of the belt. After handling the pulley, the narrow pulley must always be on the return thread.

Find the correct belt length

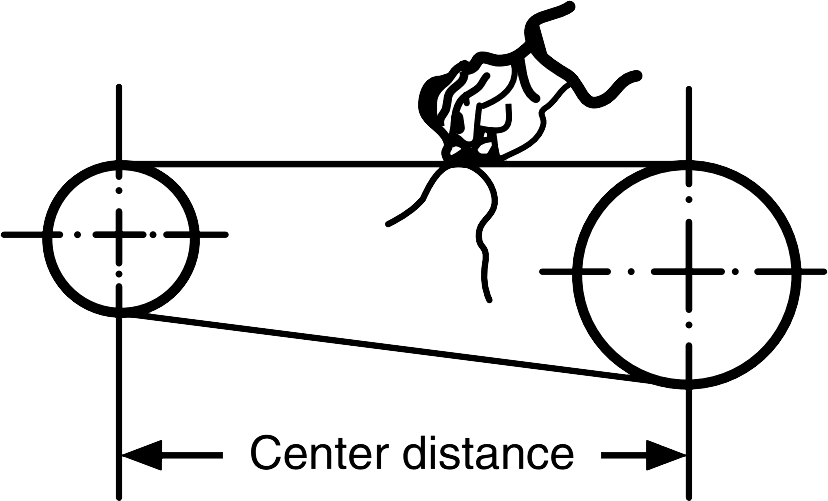

After reducing the air intake (if installed) to a minimum, use a steel rope or strap to measure. The distance between the pulleys must be kept constant. In order to obtain a good driving force and a good belt life, depending on the hardness and length of the belt, the protection zone should be from 0.5% to a maximum of 10%.

To verify the claim on the installed belt, use a pen 10 inches (or 100 mm) apart with two marks on the belt without tension. After the belt was installed, the spacing between the marks increased by a tenth of an inch (or mm), expressing the claim as a percentage.